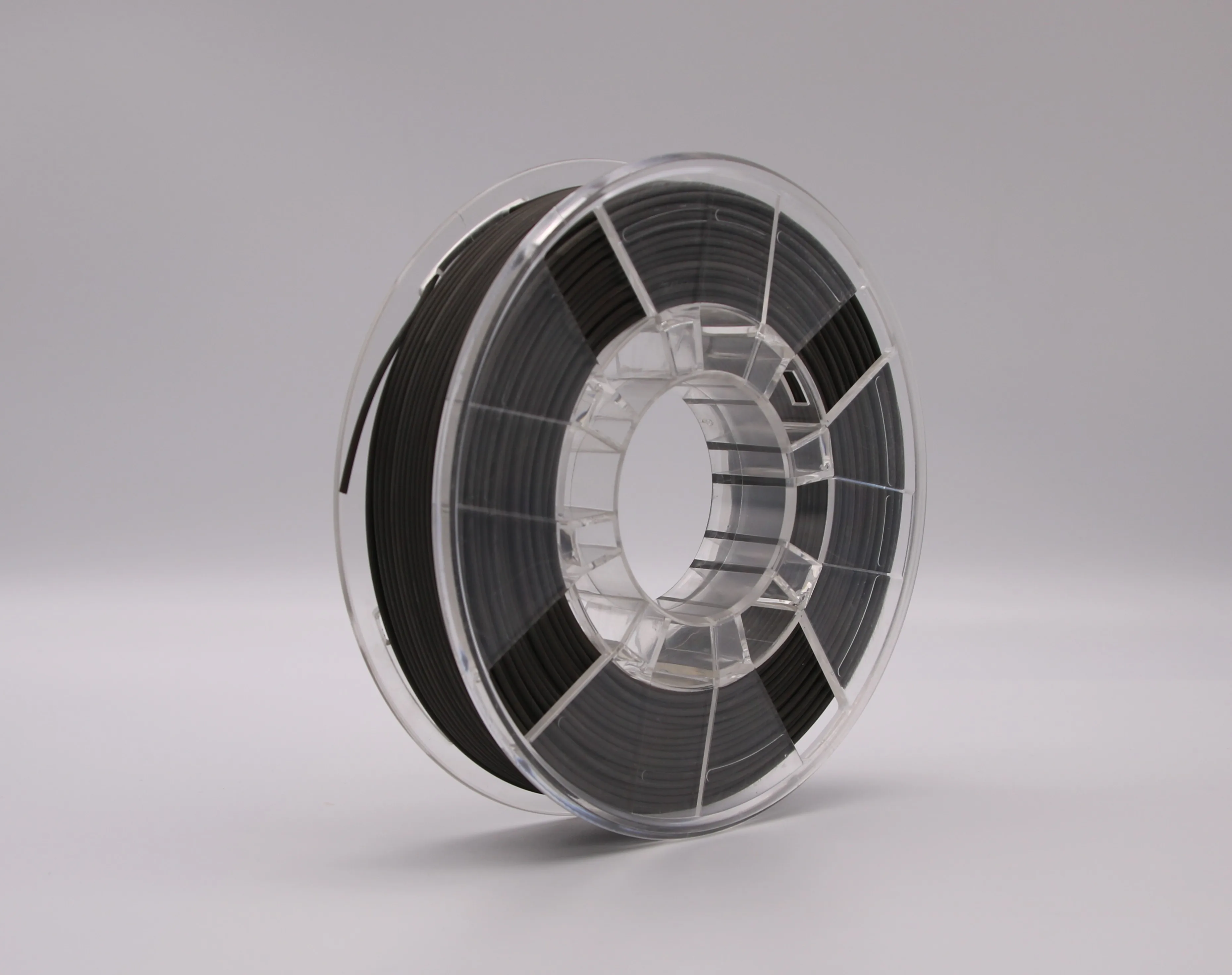

90% 316L Metal wire 3d printer filament FDM process then degreased and sintered to be obtain metal product

Category : 3D Printing & Additive Manufacturing

Price : US $316.75

Buy Now : 90% 316L Metal wire 3d printer filament FDM process then degreased and sintered to be obtain metal product

Introducing the Revolutionary 90% 316L Metal Wire 3D Printer Filament

The advent of 3D printers has revolutionized the manufacturing industry and has opened doors to endless possibilities. From printing toys to complex machinery parts, 3D printing has become an essential tool in most industries. But one of the limitations of 3D printing is the inability to produce metal objects. However, with the introduction of 316L metal wire 3D printer filament, that limitation is now a thing of the past.

What is 316L Metal Wire 3D Printer Filament?

316L stainless steel is a popular metal alloy that is commonly used in the production of medical equipment, aerospace, and marine industry parts. The 90% 316L metal wire 3D printer filament is made of a blend of 316L stainless steel and PLA (PolyLactic Acid). PLA is a biodegradable and sustainable material that ensures easy printing of the metal wires.

The FDM (Fused Deposition Modeling) Process

The filament is loaded onto the 3D printer and arranged layer-by-layer using a process that is known as FDM (Fused Deposition Modeling). During this process, the printer head melts small amounts of the filament and deposits it in layers until a 3D object is formed. This process is repeated until the entire object is complete.

Degreased and Sintered to Obtain a Metal Product

Once the object has been printed, it must go through a series of post-processing steps to transform it into a metal object. The first step is degreasing, which removes all unwanted residue, followed by sintering, which heats the object at high temperatures to fuse the metal particles together. This process is known as Metal Injection Molding (MIM) and produces fully dense metal parts.

Benefits of 90% 316L Metal Wire 3D Printer Filament

1. Ease of 3D printing – The blend of 316L metal and PLA ensures easy printing and accurate results. 2. Cost-effective – The 3D printing process is cost-effective compared to traditional manufacturing processes, which can be expensive. 3. Versatility – 3D printing with 316L metal wire filament allows for the creation of complex shapes and structures that can't be produced by traditional manufacturing processes. 4. Sustainability – PLA is a biodegradable and sustainable material that ensures the environmental impact of metal 3D printing is low. In conclusion, the introduction of 90% 316L metal wire 3D printer filament is a game-changer for the manufacturing industry. The ability to print metal objects using 3D printing technology has opened doors to endless possibilities, making it an essential tool for most industries. With the benefits of cost-effectiveness, versatility, and sustainability, metal 3D printing with 316L metal wire filament is set to become the future of manufacturing.

Post a Comment for "90% 316l Metal Wire 3d Printer Filament Fdm Process Then Degreased And Sintered To Be Obtain Metal P"